Behind Our Fabrics

The Angelico Mill

EST. 1950

Region Biella, Italy

Employees 174

Est. 1950

Owned by Massimo Angelico, 2nd generation

Mill type Wool

Fabrics Linen, Wool, Cotton-Blends

Generations of passion, foresight & relentless quality have made Angelico the prized mill it is today.

Founded in the early 1950’s, the Angelico mill has since become the jewel of Italy’s Ronco Biellese region. Today, under the guidance of founder Giuseppe Angelico’s sons, and their use of innovative techniques and technology, this family-run mill has grown into a global powerhouse of weaving, producing up to 20,000 meters of linen and wool fabrics every day for top international brands, including our own standouts like the light blue Lazio suit crafted in Angelico’s pure, richly crafted wool.

A Close Watch — Meticulous quality control ensures one of our favorite wool fabrics is finished flawlessly.

Weaving the Classic Way

It all starts with selecting the best linen and wool yarns—the foundation for Angelico’s signature fabrics. Next, they move on to combing (also known as worsting) the wool fibers to create yarns of uniform length and texture. Both wool and fine European linen, like the exceptionally soft linen used for our blue shirt-jacket, are then spun through a series of devices to reinforce and elevate the quality of the fibers. The result is a high-quality yarn which will then be turned into fabric.

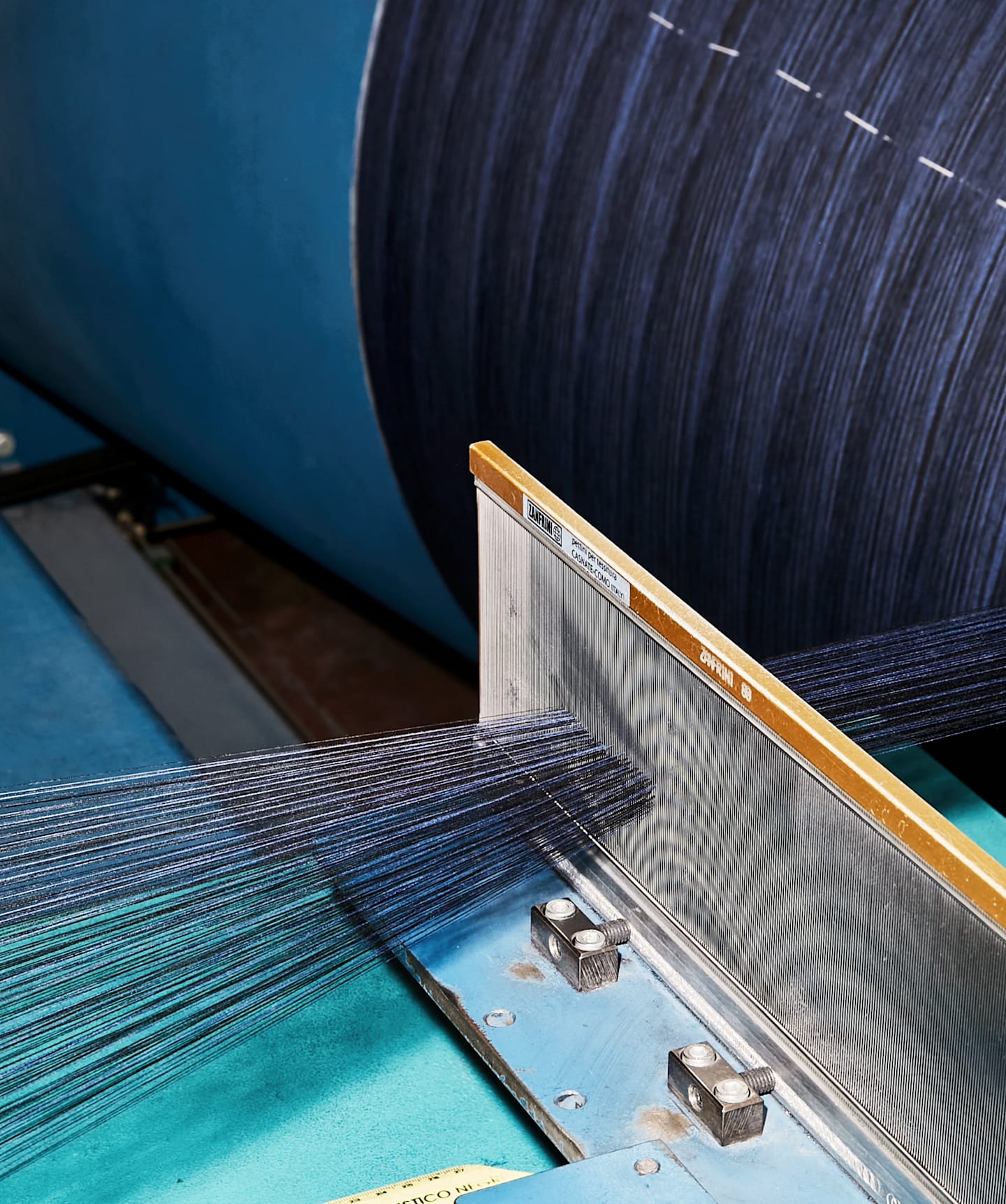

Roll With It – Worsted yarn is rolled onto massive beams, called warp or weaver's beams, to start their next phase—warping.

At this point, thousands of strands of heavy yarn are mounted on traditional weaving looms, while fine combed wool & linen yarns are mounted on jet looms. This specialized machine uses air, rather than a shuttle, to set the delicate yarns in place—keeping their softness and texture intact. Meticulous attention must be paid during this stage of the weaving cycle, as even a minor oversight can lead to a major defect in the fabric.

Finally, the fabric is finished with a series of operations like washing and other treatments that gives it a visual and structural characteristic. It is at this stage that the fabric’s soft hand and aesthetic elegance is finalized to the luxurious standards that have become synonymous with Angelico.

The Martindale Test - A friction tamper rubs the fabric with up to 10,000 circular motions to test for durability and abrasion resistance.

Angelico Today

While this revered Italian mill’s most famed offerings are pure wool and pure linen fabrics, Angelico has broadened their creativity throughout the decades with fabrics made from the finest available Mongolian cashmere, Pure wool & Egyptian cotton—and in doing so, have become purveyors of a wide range of world-class cloths. Moreover, their new “H Tech Class” offers natural stretch with memory and wicking properties, while their new washed fabrics are geared toward more casual styles.

On the aesthetic front, Angelico creates beautifully draping fabrics, sophisticated patterns and designs and rich colors that are a fixture for not only Suitsupply jackets, but for just about every major name in fashion.